Hydro-testing pumps are crucial for testing the integrity and strength of cross-country pipelines used in oil and gas transportation. They ensure that pipelines can withstand the pressure required for safe and efficient operation over long distances.

In manufacturing and industrial settings, pressure vessels such as boilers, tanks, and cylinders must undergo rigorous testing to verify their structural integrity and safety. Hydro-testing pumps are used to subject these vessels to high pressures to check for leaks or weaknesses.

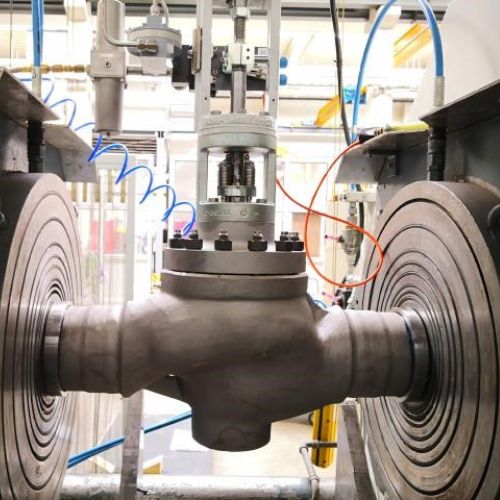

Valves play a critical role in controlling the flow of fluids in various industrial processes. Hydro-testing pumps are employed to test valves for leakage and functionality under high-pressure conditions, ensuring reliable operation and compliance with safety standards.

Hydro-testing pumps are used in the aerospace industry to test components such as hydraulic systems, fuel tanks, and structural assemblies for durability and leak-proof integrity. They ensure that aircraft components can withstand the high pressures encountered during flight.

Hydro-testing pumps are utilized in power generation plants to test steam turbines, boilers, and condensers for leaks and structural integrity. They help ensure the efficient and safe operation of equipment critical for generating electricity.

In shipbuilding, hydro-testing pumps are used to test hulls, piping systems, and ballast tanks to ensure they can withstand marine conditions and pressures encountered at sea. They verify the seaworthiness of vessels.

Hydro-testing pumps are employed in the food and beverage industry to test processing equipment such as heat exchangers, tanks, and pipelines. They ensure sanitation standards are met and prevent contamination during food production.

In pharmaceutical manufacturing, hydro-testing pumps are used to test pressure vessels, sterilization equipment, and piping systems to ensure they meet regulatory requirements for cleanliness and sterility.